Fundo do Projeto

With the rapid development of renewable energy and portable power solutions, the demand for high-quality energy storage power supplies has soared globally. A well-known energy storage device manufacturer launched a 2026 customization project, requiring Sanjun Hardware to produce 5,000 sets of custom sheet metal enclosures for its new portable energy storage power supply series. These enclosures are key components to protect internal batteries, circuit boards and cooling modules, needing to balance structural stability, waterproof and dustproof performance, heat dissipation adaptability and aesthetic consistency. The core requirements include strict dimensional precision, IP67 protection rating, impact resistance, and compatibility with modular assembly, which put forward high requirements for Sanjun’s precision sheet metal fabrication and customized service capabilities.

Processo de Fabricação de Componentes Metais de Folha Principal

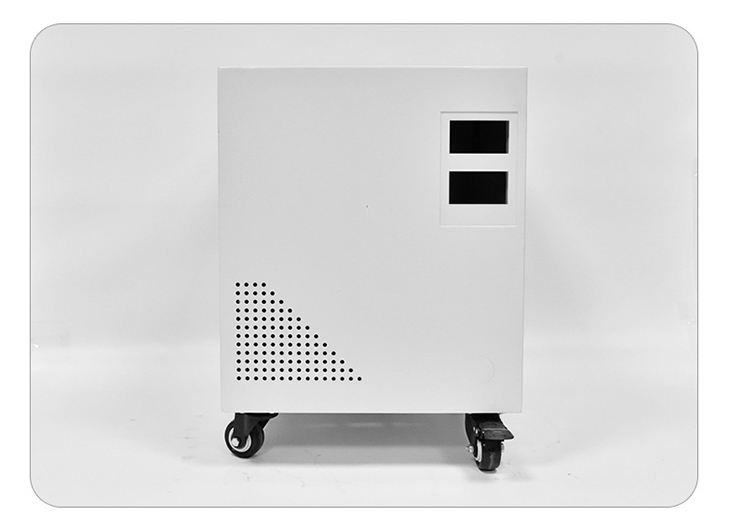

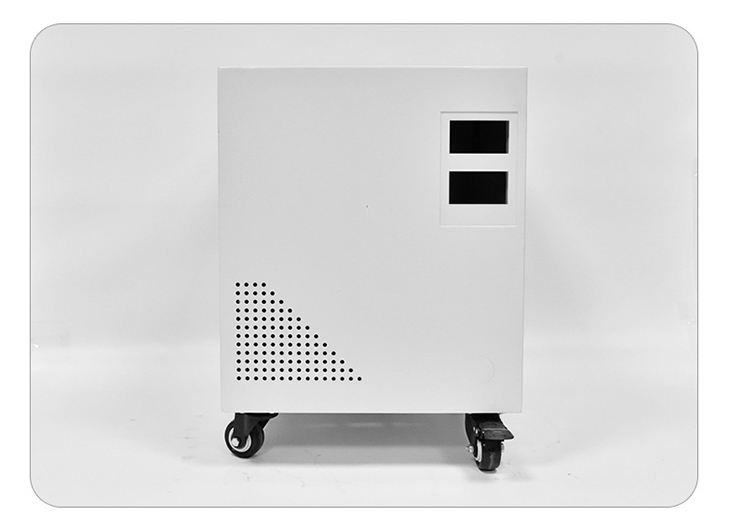

The core components of the energy storage power supply enclosure customized by Sanjun Hardware include the main enclosure body (to house batteries and circuit boards), the detachable front panel (for operation and display) and the rear heat dissipation panel. The production process strictly follows ISO 9001 quality management system and industrial sheet metal manufacturing standards, ensuring consistency and reliability of each product.

1. Seleção de materiais e Pretratamento

Main Enclosure Body: 1.2mm 5052-H32 aluminum alloy was selected for its excellent thermal conductivity, lightweight performance and corrosion resistance, which can effectively assist heat dissipation of internal components while reducing the overall weight of the energy storage power supply; Detachable Panels: 1.0mm 304 stainless steel was adopted for its high impact resistance and wear resistance, ensuring the durability of the operation and heat dissipation panels; Pre-treatment: Automated ultrasonic degreasing + chemical passivation process was used to remove oil stains, oxides and other contaminants on the surface of the materials, forming a dense passive protective film, which laid a solid foundation for subsequent surface treatment and corrosion resistance.

2. Manufactura principal de artesanato

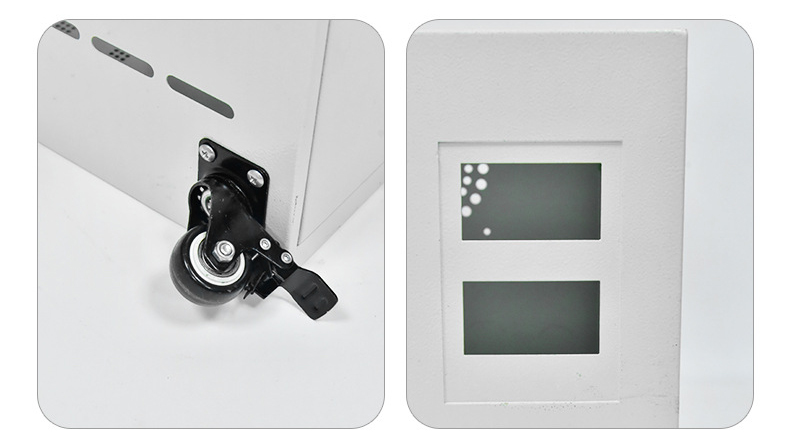

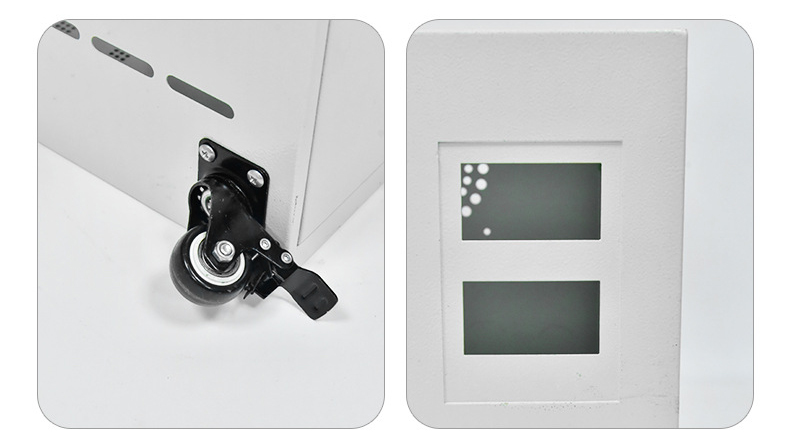

Precision Laser Cutting: 10000W fiber laser cutting machine was used, with a cutting tolerance controlled within ±0.02mm, to accurately cut the raw materials into the designed shape of the enclosure body and panels. Nitrogen assist gas was adopted to avoid oxidation of the cutting surface and reduce the heat-affected zone, ensuring the flatness of the sheet metal and facilitating subsequent bending and forming; CNC Bending & Forming: 12-axis CNC bending machine with custom fixtures was used to complete the bending and forming of the enclosure body and panels. The springback was strictly controlled within ≤0.03mm, and the edge rounding treatment was carried out to avoid sharp edges and ensure the safety of assembly and use; Heat Dissipation Structure Processing: The rear heat dissipation panel was processed with precision punching technology to form uniform heat dissipation holes, which not only ensured the heat dissipation effect but also prevented dust and water from entering; Surface Treatment: The aluminum alloy enclosure body was subjected to electrostatic spraying treatment (thickness 8-10μm) to achieve a smooth and wear-resistant surface, while the stainless steel panels were passivated to enhance corrosion resistance and maintain a metallic luster; Assembly & Calibration: Automated alignment and assembly tools were used to ensure seamless fit between the enclosure body, front panel and rear panel. Each product was subjected to assembly calibration to ensure that the internal components could be accurately installed and the modular disassembly and assembly requirements were met.

3. Controlo de qualidade e Testando

Dimensional Precision Test: Coordinate Measuring Machine (CMM) was used for full inspection of each batch of products to confirm that the dimensional tolerance met the requirement of ≤±0.03mm and there was no visible gap between components; IP67 Protection Test: According to IEC 60529 standard, dust ingress and water immersion tests were carried out to ensure that no dust or water entered the enclosure under harsh environments; Impact Resistance Test: Drop test and impact test were carried out to verify that the enclosure could withstand the impact of daily use without deformation or damage; Thermal Compatibility Test: The enclosure was tested under high and low temperature environments to ensure that it would not deform or crack, and the heat dissipation effect met the design requirements; Full Inspection Before Delivery: 100% full inspection was carried out for each product, including appearance, size, assembly and functional tests, to ensure zero defects in delivery.

Projetos desafios & Soluções de Sanjun

1. Challenge: Balancing Structural Stability and Lightweight Design

The energy storage power supply needs to be portable, so the enclosure must be lightweight, but at the same time, it needs to bear the weight of internal batteries and components, requiring high structural stability. The traditional thickened sheet metal design will increase the weight, while the thin sheet metal is easy to deform.

Solution: Sanjun’s engineering team optimized the enclosure structure through finite element analysis (FEA), adding internal reinforcing ribs to enhance the structural rigidity of the enclosure without increasing the material thickness. The 5052-H32 aluminum alloy with high strength-to-weight ratio was selected, which reduced the overall weight of the enclosure by 20% compared with the traditional design while ensuring the structural stability, fully meeting the portable and load-bearing requirements of the energy storage power supply.

2. Challenge: Ensuring IP67 Protection and Heat Dissipation Effect

The energy storage power supply is often used in outdoor or complex environments, requiring IP67 waterproof and dustproof performance, but the heat generated by internal components during operation needs to be dissipated in time, which is a contradiction between sealing and heat dissipation.

Solution: Sanjun designed a integrated sealed heat dissipation structure. The rear heat dissipation panel was equipped with waterproof and dustproof breathable valves, which could discharge the internal hot air while preventing water and dust from entering. The precision punching heat dissipation holes were designed with a special angle and density, and combined with the electrostatic spraying process with good thermal conductivity, the heat dissipation efficiency was improved by 30% while ensuring the IP67 protection rating. Sealing gaskets were added at the joint of each panel to achieve full sealing.

3. Challenge: Mass Customization with Consistent Quality

The project required 5,000 sets of enclosures, and the client demanded strict consistency in appearance, size and performance, with no visible differences between products, which put forward high requirements for the stability of mass production.

Solution: Sanjun adopted automated production lines for laser cutting, CNC bending and surface treatment, and introduced statistical process control (SPC) to monitor the production process in real time, timely adjusting the process parameters to ensure dimensional consistency. Each batch of 150 units was sampled for key indicators such as size, IP protection and impact resistance, and the unqualified products were traced and reworked. Finally, the pass rate of the whole project reached 100%, and the consistency of products was highly recognized by the client.

4. Challenge: Adapting to Modular Assembly Requirements

The client’s energy storage power supply adopted a modular design, requiring the sheet metal enclosure to be compatible with the assembly of different internal components, and the disassembly and assembly to be convenient for maintenance, which required high precision of the enclosure’s assembly holes and positioning points.

Solution: Sanjun optimized the design of assembly holes and positioning pins, using laser positioning technology to ensure the position accuracy of assembly holes within ±0.01mm. The detachable panels adopted a snap-in and screw-fixed combined design, which not only ensured the firmness of assembly but also facilitated disassembly and maintenance. Before mass production, sample assembly tests were carried out with the client’s internal components to adjust the structure in time, ensuring that the enclosure fully matched the client’s modular assembly requirements.

Resultados do Projeto

Delivery Performance: 5,000 sets of custom sheet metal enclosures were delivered 7 days ahead of the 50-day deadline, with a 100% pass rate in all quality tests, fully meeting the client’s delivery and quality requirements; Market Feedback: After 6 months of market deployment, the energy storage power supply equipped with Sanjun’s sheet metal enclosures has been highly praised by users for its stable performance, lightweight design and good durability. The client reported a 28% reduction in after-sales maintenance requests related to the enclosure and a 15% increase in product market share; Long-Term Cooperation: The client signed a 4-year strategic partnership with Sanjun Hardware, entrusting Sanjun with the sheet metal enclosure customization business for all its new energy storage power supply series, citing Sanjun’s professional customization capabilities, strict quality control and efficient delivery capacity as the core reasons for cooperation.