Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Custom sheet metal fabrication leads in design flexibility, which allows manufacturers to develop customized solutions that meet special demands. Shenzhen Sanjun Hardware & Electrical Co., Ltd. believes in customizing various sheet metal parts for clients. The customization incorporates a whole set of procedures like cutting, stamping, bending, welding, and surface treatment. The engineering personnel provides specialized design support for product requirements, and they recommend material selection and manufacturability analysis. This is aimed at providing products manufactured to precision levels and efficiently.

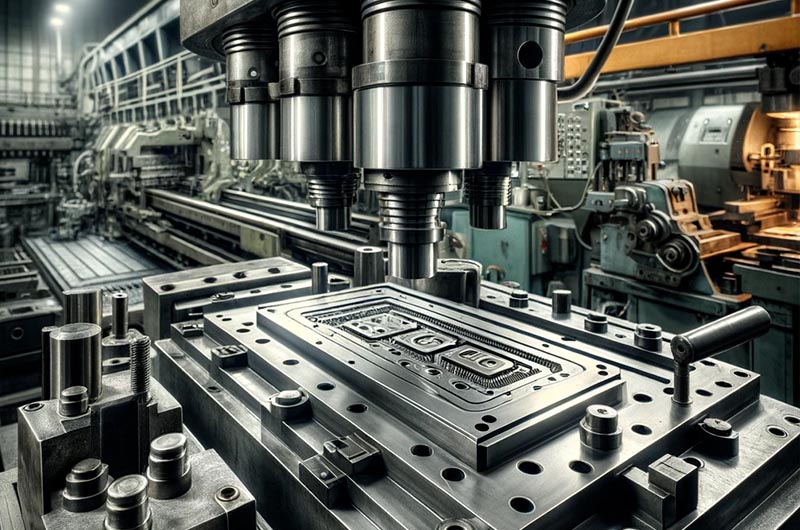

Sheet metal working is extremely friendly to complex shapes, and hence appropriate for complex geometries that require precision and accuracy. Sanjun Hardware manufacturing is accurate with accurate specifications in terms of order quantity and location of the hole. Laser cutting and CNC bending technology are employed to provide accuracy of parts and quality with complex shapes without compromising on structural strength.

Prototyping is a significant part of product development, whereby one can test and refine ideas prior to mass production. Sanjun Hardware offers rapid proofing/prototyping wherein customers can make the prototypes quickly, and more importantly, correct any changes required. This go-back-and-forth process repeated takes us to optimal product structures for mass production at lower costs.

Another benefit of bespoke sheet metal fabrication is that it lasts.We are built from mainly high-grade materials such as cold-rolled steel, galvanized steel, and stainless steel. These are selected on the basis of strength, resistance to corrosion, and tensile tolerance in the environment.

Our precise manufacturing procedures make certain that products maintain their shape and integrity with time. We manufacture using state-of-the-art methods such as CNC punching (on our Tailife XP1250 and AMADA EM2510 CNC punch presses), CNC bending, riveting (using Hager automatic riveters), and welding (including TIG, MIG, and argon arc welding). With complete automation, we provide high-quality, durable products that surpass the performance of competitor products.

Corrosion resistance is needed for products that get exposed to harsh environments. Grinding, polishing, flat coating, and silkscreen or spray painting are Sanjun Hardware’s final processes for end products. The processes enhance appearance and resist corrosion and environmental stress for the end products.

Special sheet metal manufacturing is designed to minimize material wastage by precise cutting processes. Shearing, punching, stamping, and laser cutting are some of the cutting processes. Slits and holes are simultaneously created in blanking/cutting operations.

Products manufactured through custom sheet metal production are low maintenance since they resist and last for long. Quality is initiated at raw material purchasing through to final product testing in Sanjun Hardware. In this way, processed components meet international standards, hence reducing the cost of replacement in the future.

Investment in sheet metal fabrication that is manufactured to order yields long-term income by producing quality products that will last longer when produced under conventional methods. Sanjun Hardware guarantees quality with every batch of its products, which provides clients across the globe with peace of mind.

A: Typical materials applied are carbon steel/mild steel; stainless steel (e.g., 304/316); aluminum alloys;copper/brass/bronze;nickelalloys/titaniumalloys;galvanizedsteel/coated steel/aluminum-zinc-coated steel.

A: All steps of process include QC inspections with the application of tools like coordinate measuring machines/projectors, inspection of critical dimensions to confirm they fall within customer drawing tolerances.

A: Of course! We design sealing structures according to customers’ specifications, using appropriate sealing strips/gaskets/silicone, and performing waterproof testing to guarantee IP65/IP66 compliant.

A:Surface treatments like polishing/grinding; sandblasting/shot peening; electroplating/anodizing/chrome plating/nickel plating/galvanizing; powder spraying/painting/powder coating, etc., enhance both appearance & lifespan.

A: General structural components/ordinary parts generally take 7–15 working days, whereas custom structural components/large-sized housing machinery take 20–30 working days, depending on the order scale/design complexity.

Leave a comments