Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Picking the proper casing plays a key role in the steady function of electronic gadgets, particularly in tough surroundings. If you are building factory control setups, open-air booths, or connection frameworks, the casing goes beyond mere safeguarding. It guarantees lasting efficiency. Bad heat release can shorten part duration, and missing adequate barriers can harm magnetic steadiness. In cases like open-air gadget casings, where contact with dirt, liquid, and sun rays cannot be avoided, opting for the correct substance and safety degree is mandatory.

Picking the proper casing plays a key role in the steady function of electronic gadgets, particularly in tough surroundings. If you are building factory control setups, open-air booths, or connection frameworks, the casing goes beyond mere safeguarding. It guarantees lasting efficiency. Bad heat release can shorten part duration, and missing adequate barriers can harm magnetic steadiness. In cases like open-air gadget casings, where contact with dirt, liquid, and sun rays cannot be avoided, opting for the correct substance and safety degree is mandatory. It stands as vital.

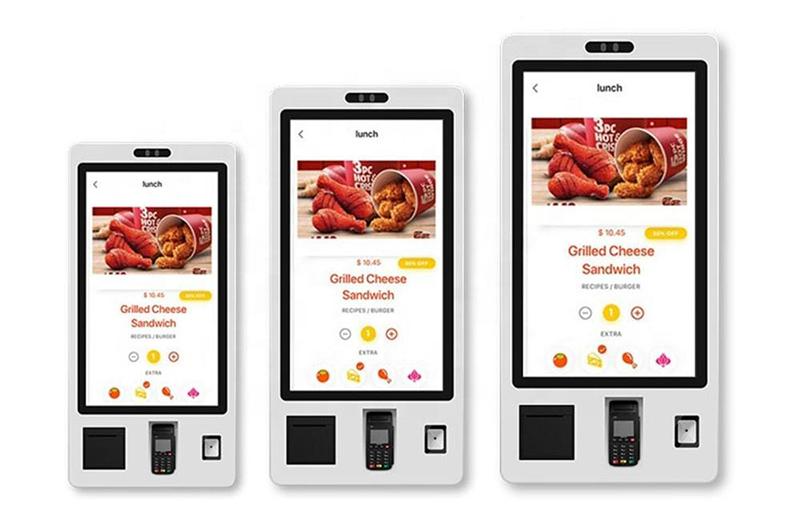

When picking a casing, grasping if your use is inside or outside forms the base. Open-air gadget casings need to withstand downpours, sun contact, and heat shifts. As an instance, we offer IP65+ safety, strengthened build plan, blast-safe lock, theft-proof setup, and warmth control plan (heat release, air flow, power warming, and so on) for self-help booths placed outside. On the other hand, inside units might require only simple dirt and unintended drip safety.

Casings frequently bear weights from attached parts or layered units. Solid build plan, tough against breeze force and shaking, proves necessary in numerous factory and open-air setups. Defense against shaking and meddling holds special importance for uses like public booths or travel systems.

Proper heat release becomes essential to keep best part function. Based on your energy level and use setting, you could use quiet cooling (openings, heat cushions) or lively cooling (blowers). Planned heat release paths, blowers/openings, or air directors appear as usual traits in our made-to-order casings. They help air movement and handle inner heats well.

EMI barriers prove crucial in settings with quick signals or where signal wholeness matters most. This holds true mainly for connection or talk gadgets. Substance conductivity and the addition of EMI seals take a main part in barrier success. We supply EMC / EMI Shielding (if needed) as portion of our casing adjustment choices.

Sheet metal gives a mix of toughness and adjustability. We utilize substances like cold-rolled steel, galvanized steel, and stainless steel. This lets us shape casings to strict details. These substances not just deliver high physical toughness but also fine shaping for tricky forms.

If you are creating a single sample or growing for bulk making, sheet metal permits sections and growth. Our technical group gives expert plan aid fitted to your item needs. It secures make-ability and cost saving through every stage.

Perfect for uses needing low mass and solid rust defense. Aluminum also backs anodizing handles which boost exterior firmness and look.

Delivers better defense to rust and physical strain. It fits well for settings needing high cleanliness rules or contact with dampness.

A budget-friendly pick with solid build wholeness. When joined with fitting exterior handles, CRS can serve even in somewhat tough settings.

Powder coating offers scrape defense and shade choices. At the same time, it boosts defense to rust and sun breakdown.

This power-chemical method boosts rust defense without harming conductivity. It suits well for exact electronics.

Applied to place a guarding layer against air damage or physical rub, especially key in rough factory places.

Our technical group gives expert plan aid fitted to your item needs. This covers DFM review and 3D shaping. Quick sample making lets us change plans fast before starting full-size making.

We can add laser-sliced gaps exactly matched with your gadget’s slots and input/output links.

Inner backs secure steady part spot even amid travel or shake-heavy use.

Buyer marks can get added too to further boost its fine look. We use silk screening or laser noting ways.

All handled parts go through exact measure and check to secure that sizes, allowances, join quality, and other signs match world rules. We use checks at each vital process step with advanced tools like point measure devices.

We hold proof under ISO 9001 and secure RoHS match for world market entry. Extra proofs like IP66 or CE/FCC can get supplied based on buyer demands.

Weather-safe casings with built-in screens get planned with sun-tough layers, closed entry boards, and inner cooling routes.

Our section casings back PLCs, HMIs, power feeds, and wires with adjustable fix choices.

EMI-barred casings include air movement routes tuned for flow or blower-based cooling setups.

We possess adjustable making skills to manage all from single samples to big-volume runs. A focused project oversight group secures schedules get met without harming standard.

We take buyer sketches/idea draws/3D shapes, sign NDAs where needed, and give local aid for overseas buyers.

A: Substance pick relies on elements like mass bounds, setting contact, fund limits. Aluminum stays light and rust-tough; stainless steel gives toughness; CRS proves cheap with solid build traits.

A: Begin by checking where the gadget will serve—inside or outside—and what it will face (dirt, downpours, substances). Next, align that to IP/NEMA guides as needed. Always think about future safety by picking greater safety degrees if changes are set.

A: Main traits cover slot slices, warmth control (blowers/openings), inner backs for PCBs/sections, fix arms, theft-proof locks, exterior handles (shade/mark) that match your mark self.

A: Warmth flaws cause part drop; weak EMI barriers harm signal wholeness. Both shape layout setup—air routes vs barrier exteriors—and substance pick (aluminum vs steel).

Inquire about making lead periods, QC steps at each phase, raw substance getting ways, adjustment bend (plan change aid), transport help (wrap/export match).

Leave a comments