Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

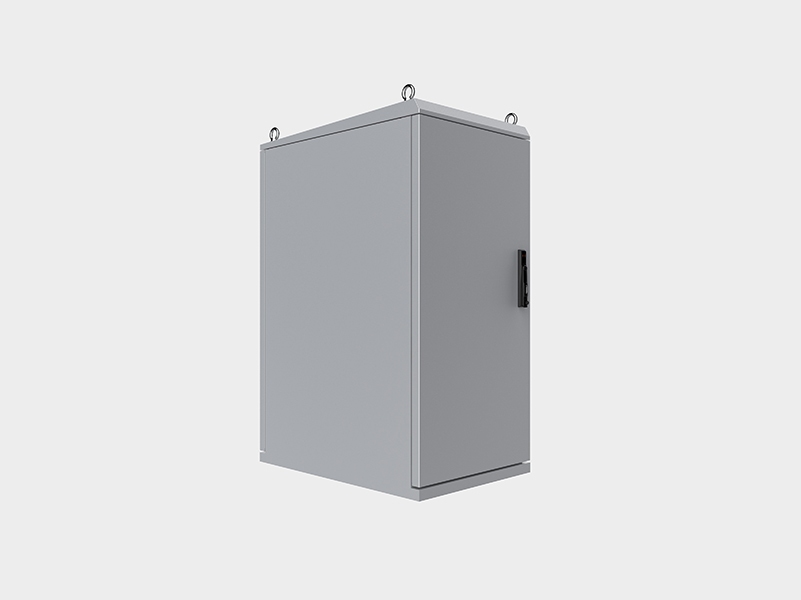

The worldwide shift to renewable energy has moved beyond a passing phase. It now drives major industry changes. As power networks grow more spread out and electric vehicle (EV) charging setups increase, the need for advanced energy storage systems (ESS) has risen sharply. Yet the performance of these systems depends on more than batteries and controls. It also hinges on the sturdy enclosures that shield and support them. For companies running power operations, the real difficulty comes in locating hardware tough enough for rough conditions while keeping the inside steady. San Jun Hardware, a leading sheet metal fabricator founded in 2010, plays a key role in this field by supplying carefully built cabinets vital for the coming wave of power control.

Power management success often comes down to fighting outside forces and inside warmth. Energy storage setups commonly face tough outdoor settings, from salty coastal zones to hot regions with strong sunlight. Without a well-planned outer case, even top-quality battery packs can break down quickly.

At San Jun Hardware, we choose materials based on the actual job site, never a one-size-fits-all approach. In coastal fast-charging stations, for instance, regular 304 stainless steel falls short. We turn to 316 stainless steel instead, which includes molybdenum to raise resistance to salt corrosion by 50%. Our wide material options—such as 6061-T6 aluminum alloy for its lower weight and strong SPCC cold-rolled steel—let us match each cabinet to its location. We add extra protection through treatments like nitric acid passivation, which forms a shielding oxide layer, and powder coatings that stand up to UV rays, stopping color fade and surface cracks in warm climates.

Large energy storage units, especially in 480kW ultra-high voltage (UHV) charging stations, produce a lot of heat. Controlling that heat calls for more than simple fans. It needs a cabinet layout that promotes air flow yet keeps everything secure. San Jun Hardware applies fluid flow modeling to arrange cooling openings effectively. With 4000W fiber laser cutters that hold tolerances of ±0.05mm, we cut exact patterns of vents and slatted openings. These designs allow good air movement while meeting IP54 or IP55 ratings for water and dust protection.

Our strength comes from blending deep technical knowledge with adaptable manufacturing. We do more than make pieces; we work closely with clients during development.

We employ 50 skilled structural engineers and put 10% of yearly earnings back into research and development. This setup gives strong OEM/ODM help. Our plant runs advanced equipment, including AMADA 8-axis CNC press brakes and robotic welding lines. Such tools let us reach tight standards, like cabinet flatness held to ≤0.1mm, which prevents part misalignment and excess heat buildup inside. Clients needing unusual brackets or curved frames for hospital payment kiosks benefit from our no-mold customization, moving fast from drawings to finished samples.

Quality forms the base of everything at San Jun Hardware. We follow the ISO9001:2008 management system and use a strict three-step checking process. Each piece goes through size checks on Coordinate Measuring Machines (CMM) for steady results in big runs. We also run tough tests, including 1500-hour salt-spray exposure and load trials, so cabinets can handle side wind forces over 500N without bending.

Our sheet metal skills apply to many fields, from healthcare to renewable power.

We have supplied 500 units of 480kW UHV charging pile cases for highway networks near the sea. Those cabinets combined 1.5mm 316 stainless steel outer shells with lighter 1.2mm 6061-T6 aluminum inner supports, striking a solid mix of strength and ease of handling. We also build smart self-service units and shared power bank stations. In one case, we produced up to 2,000 units in a single order, meeting tight rules for theft protection and cooling.

In the display market, we produce outdoor digital signage cases and IP65 self-service terminal housings. These units work with bright screens and use sturdy aluminum frames built for round-the-clock use in busy public areas. Our work keeps the look matched to client branding, with color differences held to ΔE ≤1.

During times of supply uncertainty, San Jun Hardware brings dependable service. Our 5,000-square-meter factory in the Pearl River Delta gives quick access to materials and worldwide shipping routes.

Speed matters greatly in energy projects. Our setup allows quick samples from client drawings, with full production usually finished in 15 to 20 days. For a seismic monitoring job, we shipped 1,500 exact 2U cabinets three days early, proving we can manage large orders while keeping high standards. Robotic systems handle loading and unloading on press brakes and lasers, cutting out mistakes so every unit matches the quality of the first.

Efficient power management needs a base of solid dependability. At San Jun Hardware, we supply that base with military-level standards, careful workmanship, and a focus on client needs that turns difficult energy storage issues into reliable, high-performing results.

A: Samples are generally ready within 3-7 working days after drawing confirmation. Mass production typically takes 15-20 days, depending on order volume and tooling requirements.

A: Yes. We use 8-axis CNC press brakes and CMM inspections to maintain flatness tolerances within ≤0.1mm and hole position accuracy of ±0.03mm to ensure perfect component fit.

A: We use premium materials like 316 stainless steel and 6061 aluminum, combined with 1500-hour salt-spray testing and UV-resistant powder coatings to ensure long-term resilience against corrosion and fading.

A: Absolutely. Our team of 50 structural engineers provides a one-stop solution from material selection and design optimization to mass production, supporting both 3D CAD files and custom engineering drawings.

Leave a comments