In the fast-changing world of new energy and industrial setups, a power system’s reliability often rests on the outer layer that guards its core parts. You might deploy ultra-high voltage (UHV) charging piles, energy storage systems (ESS), or detailed electrical control units. In these cases, the enclosure acts as the main shield against weather wear and physical breaks. Picking a top-notch custom cabinet goes beyond just buying. It forms a vital engineering choice that affects how long and safely your whole project stays.

For clients worldwide who need accuracy and strength, Hardware von San Jun has built a strong name since 2010 as a leading maker in high-end sheet metal work. Before you order custom power system cabinets, here is a full guide on the main points you must check to make your project work well.

Key Factors to Evaluate Before Placing Your Order

Material Durability and Environmental Adaptability

The spot where your power system will sit decides the material pick. Standard cold-rolled steel (SPCC) works great for inside uses because of its shaping ease and toughness. But for outside or rough spots, you need special materials:

- Coastal or Corrosive Areas: For places with lots of salt air, 316 stainless steel proves better. It has molybdenum, which raises corrosion resistance by 50% over standard 304 stainless steel.

- Weight-Sensitive Applications: 6061-T6 aluminum alloy often gets picked for inner supports or light outdoor cases. It weighs about 30% to 35% less than carbon steel, yet it keeps high pull strength and good heat transfer.

- Outdoor General Use: Galvanized steel or 304 stainless steel gives a fair mix of cost and performance for fighting dampness and rust.

Thermal Management and Airflow Optimization

High-power electronics, such as 480kW UHV charging modules, produce a lot of heat. Without a well-planned thermal setup, parts could fail early or work less well. You should look at:

- Ventilation Design: Search for planned heat release paths, like grid-set holes or tilted louvers. San Jun Hardware uses 30° slanted heat-dissipating slots that stop rainwater and dust, while they boost airflow by up to 25%.

- Heat Sink Integration: Check if the maker can add aluminum heat sinks or conducting plates to pull heat from delicate battery units.

Ingress Protection (IP) and Sealing Standards

For power systems, especially in outdoor or factory settings, the Ingress Protection (IP) rating cannot be overlooked.

- IP65/IP66 Protection: This keeps the cabinet dust-proof and safe from strong water streams. To reach this, you need exact fits and top sealing items like EPDM rubber gaskets.

- Sealing Integrity: Make sure the design has a frame slot for gaskets and changeable hinges to hold even gaps, ideally ≤0.3mm, to avoid leaks.

The Importance of Advanced Fabrication Techniques

Precision Bending and Hemming for Safety

A power cabinet’s built-in strength depends on the quality of its bends. San Jun Hardware works with 8-axis AMADA CNC press brakes to reach a bend tolerance of ±0.1°.

- Hemming Technology: In custom work, hemming—the step of folding a metal sheet’s edge back on itself—proves key for raising panel stiffness without more weight. It also covers sharp edges, which matters for safety in items like hospital self-service kiosk enclosures or smart school podiums.

- Springback Control: Skilled makers use custom 3D-printed dies and setting tweaks to remove “springback.” This makes the final item match the 3D CAD design just right.

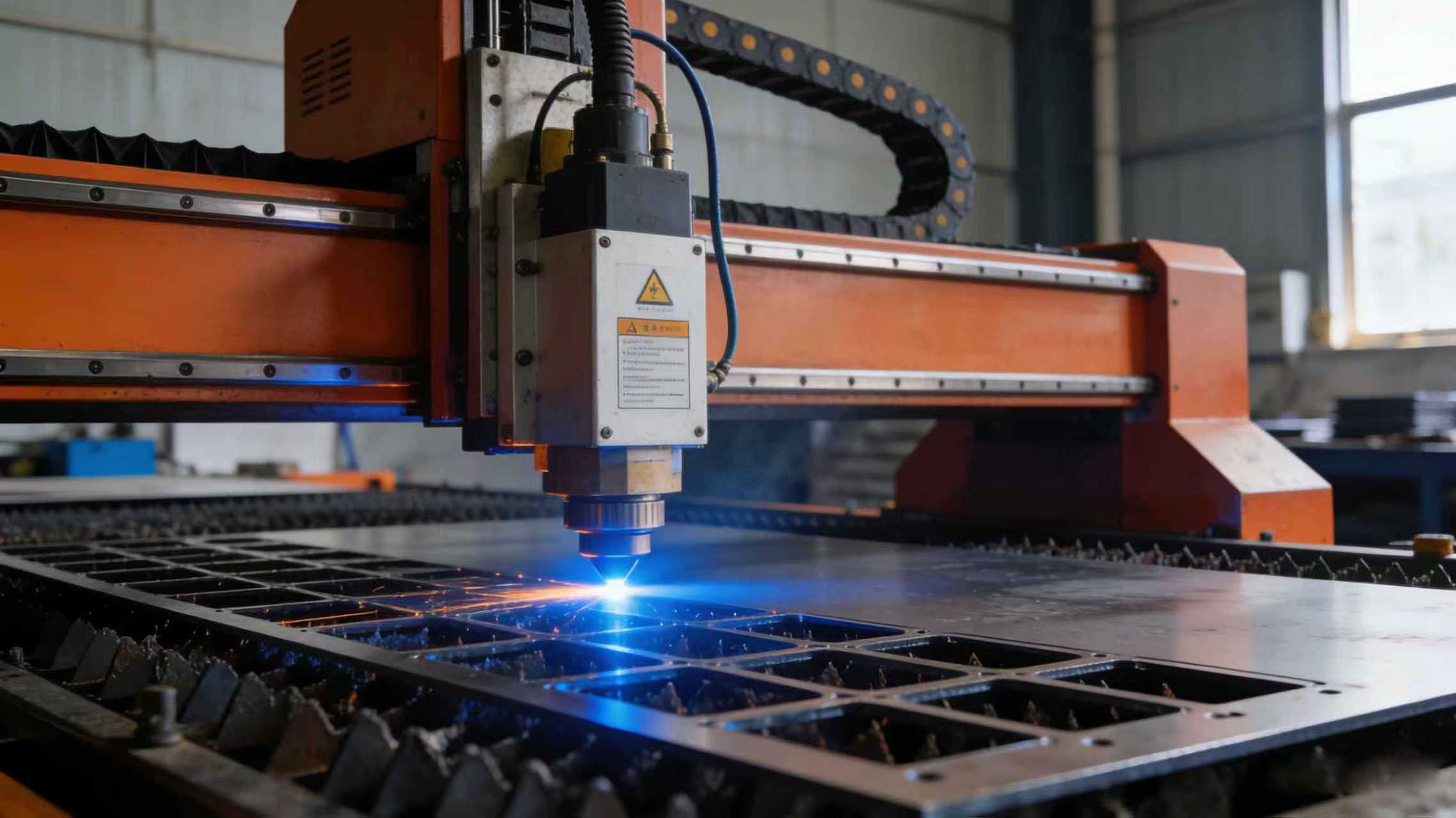

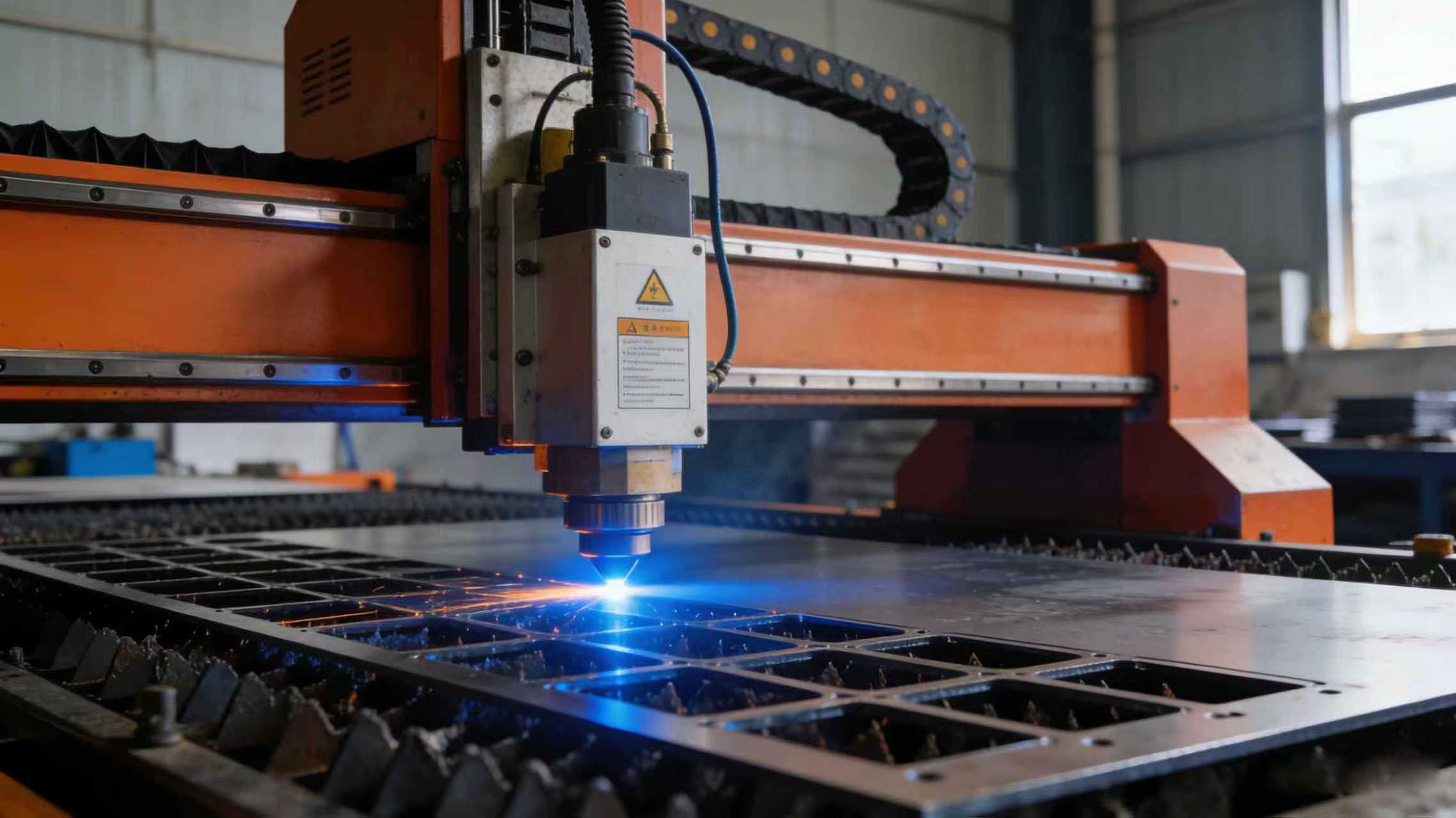

High-Precision Laser Cutting for Component Alignment

Power systems include many connectors, screens, and sensors that must line up perfectly with the cabinet’s holes.

- Tolerance Levels: Top fabrication calls for fiber laser cutting with tolerances as close as ±0.05mm. Such fineness stops setup delays and lets high-power connectors or 32-inch industrial touch screens fit right into their spots.

- Edge Quality: Laser cutting should give smooth edges without burrs (Ra ≤0.8μm). This cuts out extra grinding and guards the inner wires from harm.

Quality Assurance and Supply Chain Reliability

Rigorous Testing Protocols

A trusted supplier does more than build. They also test. Before you order, confirm the maker’s testing skills:

- Dimensional Verification: Use of Coordinate Measuring Machines (CMM) to check hole spots and cabinet flatness (often needed to be ≤0.1mm to prevent part shifts).

- Environmental Tests: This covers 1500-hour salt-spray testing for seaside setups, IP65 waterproof checks, and high/low-temperature runs.

- Structural Load Tests: Confirm the cabinet can take side wind loads (e.g., 500N) or shake levels (e.g., 1.5g) for quake monitoring or outdoor steadiness.

OEM/ODM Support and Flexible Production

Every power system job brings its own needs, so OEM/ODM technical support becomes crucial.

- Flexible Capacity: Your supplier should manage from small prototype batches for R&D to large production of thousands. San Jun Hardware, for example, can send 2,000 units in 45 days while keeping a 100% pre-delivery check pass rate.

- Design for Manufacturability (DFM): A solid partner will look over your CAD files to give a DFM review. This helps improve product builds and cut buying costs.

Why Choose San Jun Hardware for Your Power System Projects

San Jun Hardware gives a complete one-stop answer for the power and energy fields. Our skills cover a wide set of in-demand items, including:

- New Energy Solutions: Custom sheet metal cases for NEV charging piles and IP65/66 enclosures for energy storage systems (ESS).

- Smart Terminals: IP65 self-service terminal integrated machine shells, hospital self-service kiosk enclosures, and outdoor custom digital signage shells.

- Industrial Precision: Rackmount enclosures for seismic early-warning equipment and high-precision industrial touch display shells.

By blending modern tools like 4000W fiber lasers and robotic welding with a tough quality view, San Jun Hardware makes sure every cabinet mixes “rigidity and flexibility”. Our focus on clients means we put 10% of yearly profits into R&D to keep up with market shifts.

Schlussfolgerung

Whether you need 316 stainless steel for a coastal charging network or lightweight aluminum brackets for a mobile power bank cabinet, we provide professional, cost-effective solutions that accelerate your product’s time to market.Contact our team today to discuss your project, request a quotation, or submit drawings for prompt DFM review.

FAQ (häufig gestellte Fragen)

Q: Can you achieve IP65 or IP66 ratings for outdoor power cabinets?

A: Yes, we build them with strong EPDM rubber gaskets and specially shaped door seals. Every unit goes through thorough high-pressure water spray testing so the inside stays fully protected in wet outdoor conditions.

Q: What is the typical lead time for a custom cabinet order?

A: For standard or simpler designs, production normally takes 7–15 working days. More detailed custom work or bigger batch orders usually need 20–30 working days from drawing approval to shipment.

Q: Do you support small-batch prototyping before mass production?

A: Yes, we handle small runs easily. Send us your drawings, and we will make samples quickly so you can check fit, quality, and function before moving to full production quantities.

Q: What materials do you commonly use for power system enclosures?

A: Our main choices include cold-rolled steel (SPCC), 304 stainless steel, 316 stainless steel, and 6061-T6 aluminum alloy. We pick the right one depending on the installation environment and how much weight matters for your projects.

Hinterlasse einen Kommentar