Fundo do Projeto

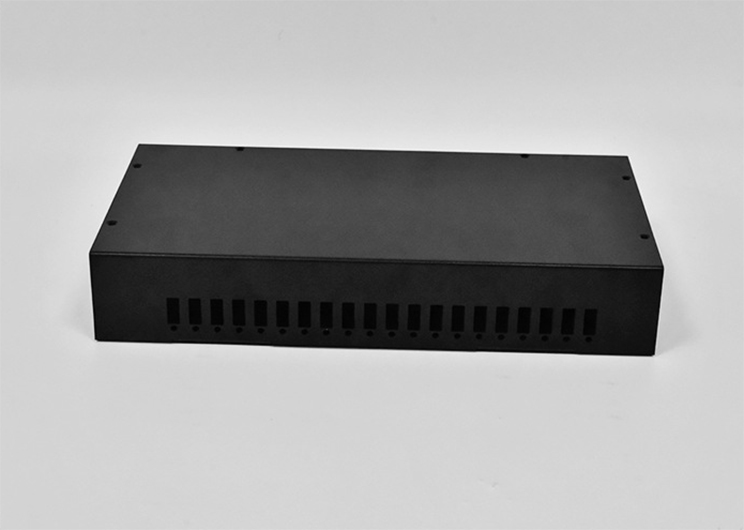

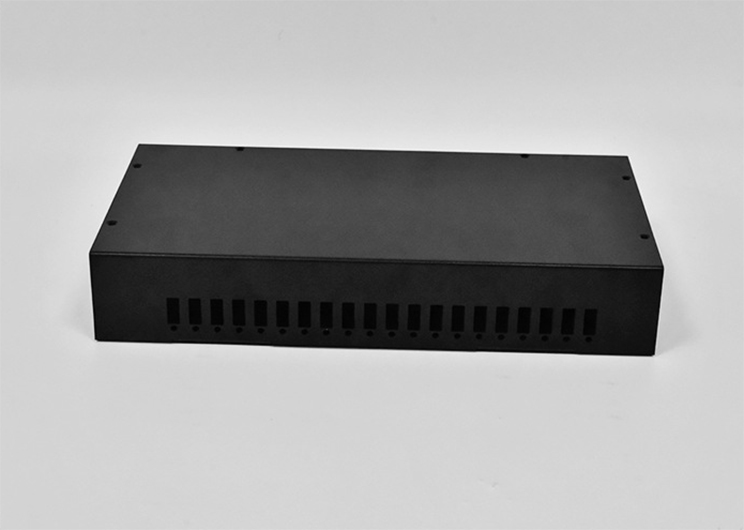

With the rising demand for portable and high-fidelity audio equipment, a professional audio manufacturer launched a 2026 customization project, entrusting Sanjun Hardware to produce 3,000 sets of galvanized sheet chassis enclosures for its new USB amplifier box series. These enclosures serve as the core protective structure for internal amplifier modules, USB interfaces, and circuit boards, requiring a perfect balance of corrosion resistance, structural rigidity, precise interface alignment, and cost-effectiveness. The core requirements include dimensional tolerance ≤±0.04mm, galvanized layer thickness 8-10μm, good heat dissipation performance, seamless fit with USB and audio interfaces, and compatibility with batch assembly. This project put forward specific requirements for Sanjun’s galvanized sheet processing technology and custom matching capabilities.

Processo de Fabricação de Componentes Metais de Folha Principal

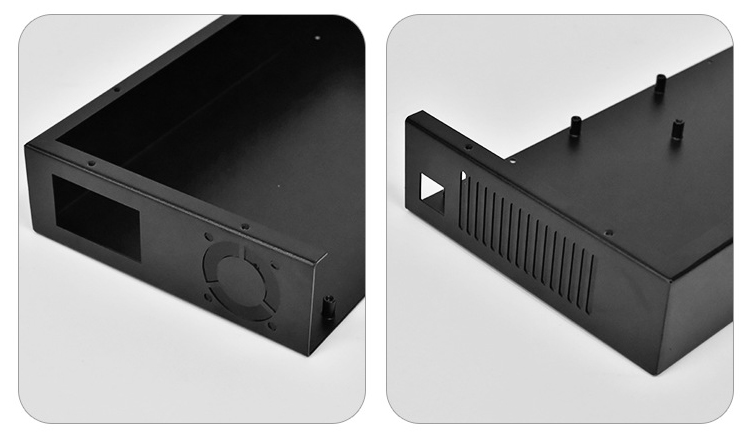

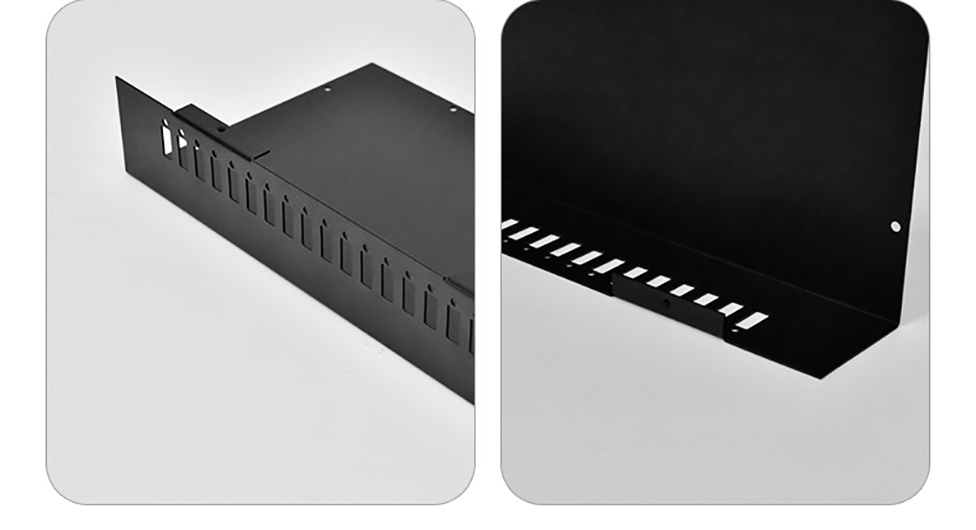

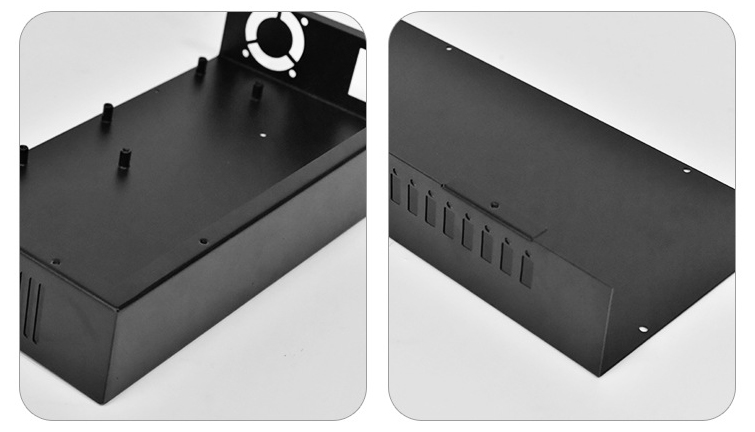

The core components of the USB amplifier box chassis customized by Sanjun Hardware include the main chassis body (housing amplifier modules and circuit boards), the front panel (reserving USB and audio interfaces), and the rear heat dissipation panel. The production process strictly follows ISO 9001 quality management system and galvanized sheet processing standards, ensuring the stability and consistency of each product while highlighting the advantages of galvanized materials.

1. Seleção de materiais e Pretratamento

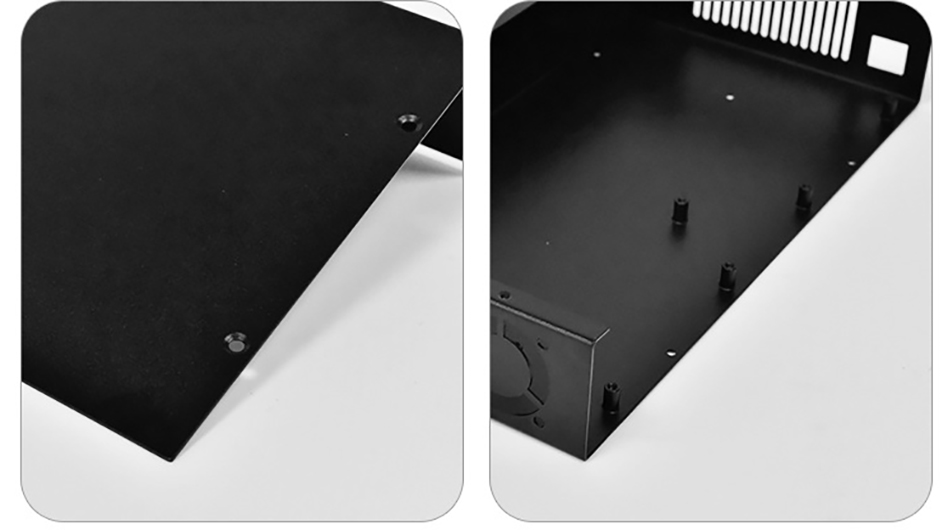

Main Chassis & Panels: 1.0mm hot-dip galvanized steel sheet was selected for its excellent corrosion resistance, high structural rigidity, and cost-effectiveness, which can effectively prevent oxidation and rust in daily use and adapt to different use environments; Pre-treatment: A targeted pre-processing process was adopted for galvanized sheets—first, automated ultrasonic degreasing was used to remove oil stains and contaminants on the surface, then pickling and passivation were carried out to remove surface oxides and enhance the adhesion of the galvanized layer. Special anti-scratch protection measures were taken during processing to avoid damage to the galvanized layer, ensuring the corrosion resistance of the final product.

2. Manufactura principal de artesanato

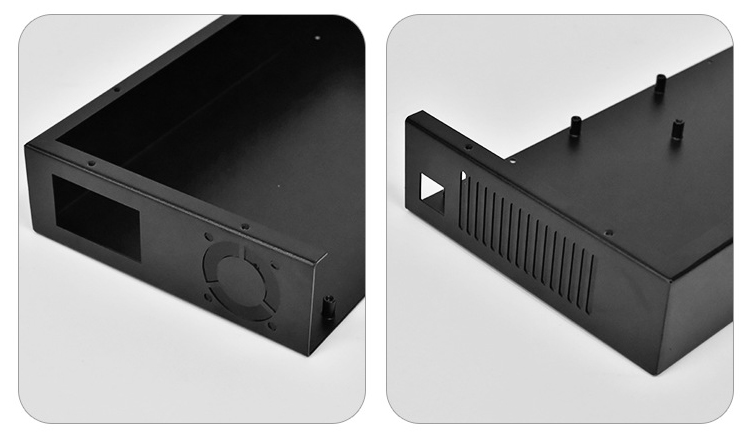

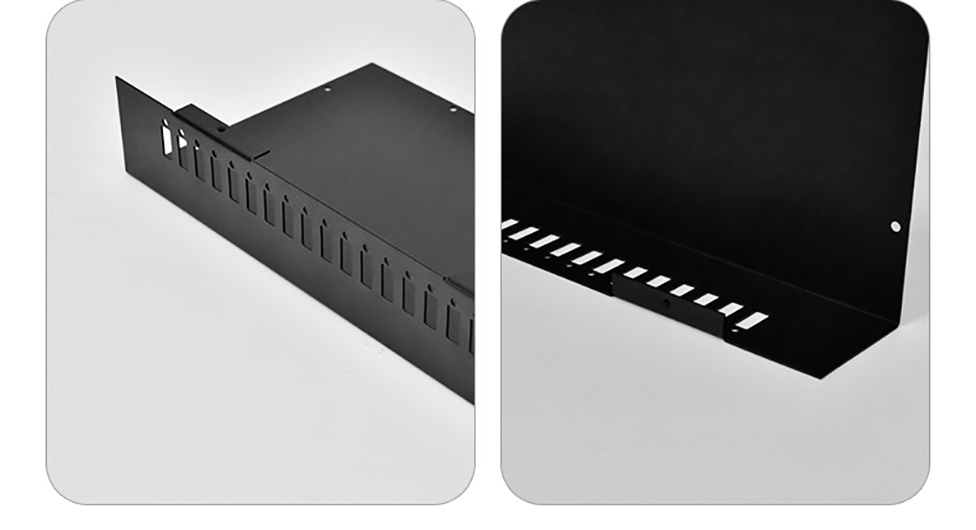

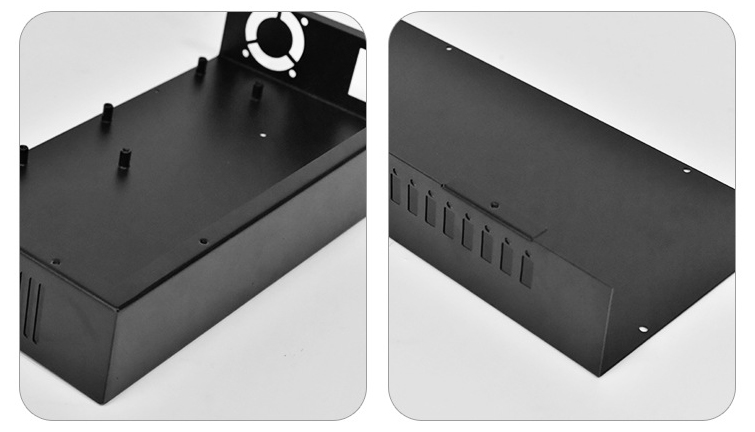

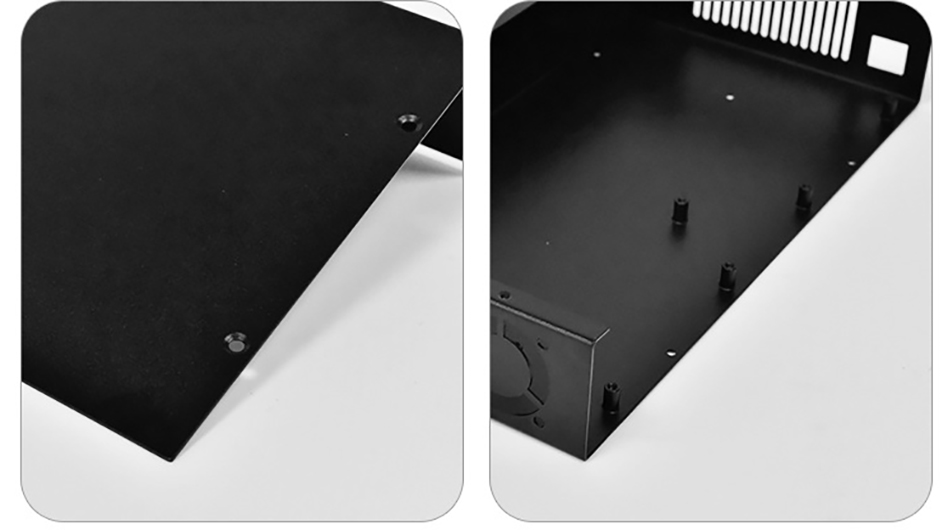

Precision Laser Cutting: 8000W fiber laser cutting machine was used, with cutting tolerance controlled within ±0.02mm, to accurately cut the galvanized sheet into the designed shape of the chassis body and panels. Nitrogen assist gas was adopted to avoid oxidation of the cutting surface and damage to the galvanized layer, ensuring the flatness of the sheet metal and facilitating subsequent bending and forming; CNC Bending & Forming: 10-axis CNC bending machine with custom anti-scratch fixtures was used to complete the bending and forming of the chassis. The springback was strictly controlled within ≤0.03mm, and the edge rounding treatment was carried out to avoid sharp edges and ensure the safety of assembly and use. Special attention was paid to the bending angle of the chassis to ensure the fit of internal components; Interface Positioning & Processing: The front panel’s USB and audio interface holes were processed by precision punching technology, with position accuracy controlled within ±0.01mm, ensuring seamless fit with the interfaces and avoiding poor contact. The hole edge was polished to prevent damage to the interface; Surface Finishing: After sheet metal processing, the chassis was subjected to secondary galvanizing repair treatment for the cutting and bending positions, ensuring the integrity of the galvanized layer. Finally, electrostatic dust removal was carried out to achieve a smooth and clean surface; Assembly & Calibration: Automated alignment tools were used to assemble the chassis body, front panel, and rear panel, ensuring seamless fit and no loose gaps. Each product was subjected to interface assembly calibration to ensure that USB and audio interfaces could be accurately installed and used normally.

3. Controlo de qualidade e Testando

Dimensional Precision Test: Coordinate Measuring Machine (CMM) was used for sampling inspection of each batch of products to confirm that the dimensional tolerance met the requirement of ≤±0.04mm and the interface position was accurate; Galvanized Layer Test: Thickness gauge was used to detect the galvanized layer, ensuring the thickness was between 8-10μm, and salt spray test was carried out for 48 hours to verify no rust or corrosion; Heat Dissipation Test: The chassis was tested under the working state of the amplifier to ensure that the heat generated by internal components could be effectively dissipated, and the chassis surface temperature met the design requirements; Interface Fit Test: Each chassis was assembled with USB and audio interfaces to verify seamless fit and normal signal transmission; Full Inspection Before Delivery: 100% full inspection was carried out for each product, including appearance, size, galvanized layer integrity, and assembly effect, to ensure zero defects in delivery.

Projetos desafios & Soluções de Sanjun

1. Challenge: Protecting Galvanized Layer During Processing

Galvanized sheets are prone to galvanized layer peeling, scratching, or oxidation during laser cutting, bending, and handling, which will affect the corrosion resistance of the chassis and the overall appearance.

Solution: Sanjun optimized the processing process and tools—custom anti-scratch fixtures were used during bending and clamping to avoid direct contact between the tool and the galvanized layer; the laser cutting parameters were adjusted to reduce the heat-affected zone and avoid galvanized layer melting and falling off; the processed products were placed in a dust-free and dry environment, and anti-scratch films were pasted on the surface. After processing, secondary galvanizing repair was carried out for the damaged positions, ensuring the integrity and corrosion resistance of the galvanized layer.

2. Challenge: Ensuring Precise Alignment of USB & Audio Interfaces

The USB amplifier box has high requirements for the position accuracy of the interface holes on the chassis front panel. Even a small deviation will lead to poor fit between the interface and the hole, affecting the installation and use of the product.

Solution: Sanjun adopted laser positioning and precision punching integrated technology to ensure the position accuracy of the interface holes within ±0.01mm. Before mass production, sample assembly tests were carried out with the client’s USB and audio interfaces to adjust the hole position in time. During mass production, real-time positioning detection was added to the punching process, and unqualified products were removed in time, ensuring that the interface alignment of each chassis met the requirements.

3. Challenge: Balancing Structural Rigidity and Lightweight Design

The USB amplifier box is mostly portable, so the chassis needs to be lightweight, but at the same time, it needs to have sufficient structural rigidity to protect internal components from external impact, which is a key balance point for galvanized sheet chassis design.

Solution: Sanjun’s engineering team optimized the chassis structure through finite element analysis (FEA), adding lightweight reinforcing ribs inside the chassis to enhance structural rigidity without increasing the material thickness. The 1.0mm hot-dip galvanized sheet with high strength-to-weight ratio was selected, which reduced the overall weight of the chassis by 15% compared with the traditional design while ensuring structural stability, fully meeting the portable and protective requirements of the USB amplifier box.

4. Challenge: Batch Consistency of Galvanized Layer and Appearance

The project required 3,000 sets of chassis, and the client demanded strict consistency in the thickness of the galvanized layer and the surface appearance of the product, with no obvious differences between batches, which put forward high requirements for the stability of mass production.

Solution: Sanjun adopted automated production lines for laser cutting, bending, and galvanizing repair, and introduced statistical process control (SPC) to monitor the processing parameters and galvanized layer thickness in real time. Each batch of 100 units was sampled for galvanized layer thickness detection and appearance inspection, and the unqualified products were traced and reworked. The same batch of galvanized sheets was used for production to avoid differences in material performance, ensuring that the batch consistency of the product met the client’s requirements.

Resultados do Projeto

Delivery Performance: 3,000 sets of custom galvanized sheet chassis enclosures were delivered 4 days ahead of the 40-day deadline, with a 100% pass rate in all quality tests, fully meeting the client’s delivery and quality requirements; Market Feedback: After 5 months of market deployment, the USB amplifier boxes equipped with Sanjun’s galvanized sheet chassis have been highly praised by users for their corrosion resistance, stable structure, and perfect interface fit. The client reported a 30% reduction in after-sales maintenance requests related to the chassis and a 18% increase in product sales; Long-Term Cooperation: The audio manufacturer signed a 3-year strategic partnership with Sanjun Hardware, entrusting Sanjun with the sheet metal chassis customization business for all its USB amplifier box series and new audio equipment, citing Sanjun’s professional galvanized sheet processing capabilities, strict quality control, and efficient delivery capacity as the core reasons for cooperation.