Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Classrooms today look nothing like they did ten years ago. Kids walk past touch-screen kiosks on the way to class, teachers control lessons from liftable podiums, and small robots check temperatures at the gate. All that new gear has to live somewhere safe, clean, and tough enough to survive hundreds of little hands every day. The trick is finding metal boxes and frames that protect expensive electronics without turning the school into a cold factory. A well-made enclosure keeps the technology running, keeps fingers safe, and still looks like it belongs in a school instead of a warehouse.

San Jun Hardware opened its doors in 2010. From the start, we concentrated on turning flat sheets of steel and aluminum into finished parts that actually work in the real world. Our 5,000-square-meter shop runs modern 3000W laser cutters and AMADA CNC bending machines, and everything follows the ISO 9001 rules.

We make pieces for medical carts, power cabinets, charging stations, and – more and more often – schools and universities. When a school project lands on our desk, we already know the drill: it has to be strong, easy to wipe down, free of sharp edges, and good-looking enough that students and teachers don’t mind seeing it every day.

Schools want gear that works harder and lasts longer. We build the metal shells that make those ideas possible.

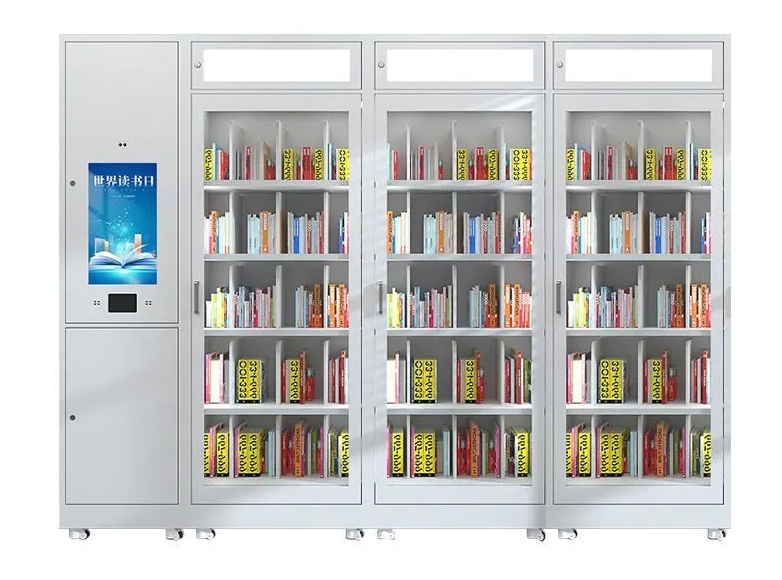

Picture a busy library corridor. Students rush in between classes to grab a reserved book or drop off a newspaper. Our Newest Service Book/Newspaper Vending Machine Enclosure stands there ready for the job.

It doesn’t look like the usual gray box. Clean lines and a soft matte finish come from sand-blasted cold-rolled steel or anodized aluminum alloy. Fingerprints wipe right off, and scratches are hard to make. A single big sheet of toughened glass covers the front so kids can see exactly what’s inside. The card reader and touch screen sit flush with the surface – no sticking-out parts to catch sleeves or backpacks. Thin LED strips along each shelf light up in gentle blue when a book is waiting, pointing the student straight to the right spot. The whole thing feels friendly instead of industrial, yet it can take the daily pounding from hundreds of users.

Teachers spend hours at the front of the room. Standing too long hurts the back; sitting too long puts the screen at the wrong height. Our Latest Liftable Smart School Classroom Podium Enclosure fixes that with a quiet electric lift.

The body is mostly cold-rolled steel, sometimes mixed with wood-grain panels for warmth. Every corner is rounded over, and we spray on antimicrobial powder coat, so a quick wipe with disinfectant keeps it clean between classes. Two strong motors move the top up and down smoothly. If a child’s hand or a stack of books gets in the way, the motor stops and backs up a little – no pinched fingers. Teachers can lower it to sit comfortably for prep periods or raise it high enough to walk around while still seeing the 23.8-inch screen. After a full day on their feet, most teachers tell us the difference is night and day.

Since the pandemic, many schools have temperature-checking robots at the entrance or moving around playgrounds. Those machines live half outside, so sun, rain, dust, and frost try to kill them every day. Our Semi-Outdoor AI Robot Enclosure is built for exactly that fight.

We start with galvanized steel and add a thick outdoor-grade powder coat that shrugs off rust and fading. Every bend and weld has to be perfect because the shape is rarely a simple box – these robots have arms, cameras, and screens sticking out at odd angles. The finished shell still keeps an IP65 dust-and-water rating while letting air flow to the cooling fans inside.

Good intentions only get you so far; the metal itself has to hold up.

Sharp corners have no place in a primary school. We roll every visible edge and use food-grade rubber strips where panels meet. The base steel goes through pickling and phosphating before we spray electrostatic powder coat, so even if someone chips the surface with a chair, rust doesn’t creep in. Colors stay bright year after year instead of chalking out like cheap paint.

Modern screens and sensors leave no room for sloppy fits. Our laser cutters hold ±0.1 mm on thin sheets, and the AMADA brakes repeat bends within a couple of hundredths. That matters when a 23.8-inch touch monitor has only 2 mm of clearance around the edges. One wrong bend and the glass won’t sit flat.

We handle the whole job in-house: laser cutting, punching, bending, welding, coating, and assembly. Because we don’t need expensive molds for most school projects, a new design can go from drawing to finished sample in two or three weeks and into full production right after approval.

Smart classrooms only work when the hardware stays safe and clean for years. San Jun Hardware builds the metal parts that turn good ideas into gear that actually survives real schools. From book vending machines that look inviting to liftable podiums that save teachers’ backs, from outdoor robots that keep checking temperatures in the rain – we make the tough, pretty, kid-proof shells that let the technology do its job. Talk to us about your next project, and we’ll turn your sketches into metal that’s ready for tomorrow’s students.

A: Most pieces start with cold-rolled steel or aerospace-grade алюминий alloy. We add antimicrobial powder coat, galvanized steel with outdoor spray, or anodizing, depending on where the unit will live.

A: Yes. Complex robot shapes and odd-angle podiums are routine for us. High-precision CNC bending and welding let us hit tight tolerances without needing molds.

A: We usually quote the same day or the next day. Once drawings are signed off and the deposit is in, standard custom jobs without tooling ship in 15 to 20 days.

A: Every edge gets fully rounded corners, we use antimicrobial finishes, and the whole structure is built heavy enough to take daily knocks without bending or breaking.

Leave a comments